Best Roof Underlayments 2026: Top Picks and Buying Guide

Your shingles get all the glory, but the underlayment does the heavy lifting. As the second line of defense against moisture, wind, and ice dams, selecting the right underlayment is arguably more critical than the top layer itself. In 2026, the market has shifted decisively toward high-performance synthetics, but is traditional felt dead? Not quite.

Whether you are re-roofing a historic home or installing a modern standing seam metal roof, this guide cuts through the marketing noise to give you the absolute best underlayment options for every budget and material.

Why Roof Underlayment Matters

Think of underlayment as your roof’s raincoat. Even the best-installed shingles can lift during a hurricane, or crack under extreme UV exposure. When that happens, the underlayment prevents water from rotting your wooden deck. It also serves as a temporary barrier during installation, protecting your home before the final roof is laid.

How We Chose the Best Underlayments

We evaluated over 30 top-rated products based on four critical criteria:

- Tear Strength: Can it survive a roofer walking on it or a sudden wind gust?

- Exposure Time: How long can it sit in the sun before degradation starts?

- Walkability: Does it offer a non-slip surface for installers (critical for safety)?

- Sealability: How well does it seal around nails to prevent leaks?

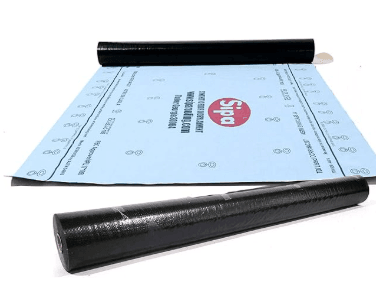

SIPA 100 GSM Synthetic Waterproof Roof Underlayment

The SIPA 100 GSM Synthetic Underlayment offers a strong, reliable waterproofing layer for both residential and commercial roofing projects. Designed for durability and UV protection, it withstands tough weather conditions while providing a secure foundation under metal or asphalt roofing.

Features

- 1000 square feet coverage

- Performance exceeds ASTM D4869 and ASTM D226

- Water resistant and UV protected for 60 days

- Prevents buckling, warping, and cracking

Pros

- Ideal for steep and low-slope roofs

- Excellent moisture resistance

- Durable against environmental damage

Cons

- Currently unavailable for purchase

ArmorLay 25 Synthetic Roof Underlayment

ArmorLay 25 is a synthetic underlayment engineered to provide superior slip resistance and waterproof protection under roofing materials. With UV resistance and ASTM certification, it is built for long-term reliability even in challenging climates.

Features

- 1000 square feet coverage per roll

- Meets ASTM D4869 and D226 standards

- Slip-resistant bottom for safety on steep slopes

- Water resistant and UV protected for 60 days

Pros

- Easy to install and remove

- Excellent walk-ability

- Strong UV protection

Cons

- Heavier roll compared to other synthetics

Waterproof Membrane 430 Sq Ft Orange PE Fabric

This waterproof membrane made from high-density PE film offers reliable moisture protection for floors, showers, and roof areas. Designed to prevent mold growth, it is an essential layer for long-lasting construction projects.

Features

- Coverage of 430 square feet per roll

- Thickness of 20 mils for extra strength

- Highly waterproof and resistant to tearing

- Flexible and easy to cut to size

Pros

- Ideal for wet environments like bathrooms

- Prevents moisture, mold, and mildew

- Lightweight and easy to install

Cons

- Not recommended for heavy load-bearing surfaces

What to Look for in Roof Underlayment

When shopping for underlayment, check the label for these three specs:

- Perm Rating (Breathability): If you have a poorly ventilated attic, you want a “breathable” underlayment to let moisture escape from inside the house. If your attic is sealed/conditioned, a vapor barrier is fine.

- UV Exposure Limit: How long can it sit in the sun? Felt ruins in days. Good synthetics last 3 to 6 months.

- Temperature Range: Especially for metal roofs, ensure the product is rated for at least 240°F.

Proper ventilation pairs with good underlayment. Consider upgrading your system with the best ridge vents for metal roofs or installing roof exhaust fans to reduce moisture buildup.

Felt vs. Synthetic Underlayment: The Showdown

Is felt dead? In 2026, mostly yes. Here is why synthetic has taken over the market.

| Feature | Synthetic | Asphalt Felt (#30) |

|---|---|---|

| Weight | Light (20-30 lbs/roll) | Heavy (50-60 lbs/roll) |

| Tear Strength | High (Hard to tear) | Low (Rips easily) |

| Coverage | 10 Squares (1000 sq ft) | 2 Squares (200 sq ft) |

| Safety | Non-slip coatings | Slippery when wet |

| Cost | $$ | $ |

Installation Tips and Best Practices

Even the best product fails if installed poorly. Follow these golden rules:

- Overlap Correctly: Usually 4 inches on horizontal seams and 6 inches on vertical seams.

- Use Cap Nails: Never use standard staples for synthetic underlayment. They pull through easily. Use plastic cap nails or cap staples to seal the holes.

- Go High at the Eaves: In snow zones, install “Ice and Water Shield” (peel-and-stick) on the bottom 3-6 feet of the roof deck before laying the synthetic underlayment.

Safety is paramount. Ensure you have the best roofing shoes for traction and proper roof harnesses before stepping onto the slope.

Frequently Asked Questions (FAQ)

Can synthetic underlayment be left exposed to weather?

Yes, most synthetic roof underlayments can be left exposed for short periods during construction. Products like SIPA 100 GSM and ArmorLay 25 provide UV protection and weather resistance for up to 60 days, but final roofing should be installed promptly for maximum protection.

What is the best roof underlayment for metal roofing?

Synthetic underlayments such as SIPA 100 GSM are ideal for metal roofs because they offer excellent moisture resistance, prevent wrinkling, and can handle temperature fluctuations without degrading, unlike traditional felt paper.

Is waterproof membrane fabric good for floors and showers?

Absolutely. High-density polyethylene (PE) waterproof membranes are specifically designed to protect tile floors, showers, and wet areas by preventing moisture infiltration, mold, and mildew. They are flexible, durable, and easy to install under ceramic or stone tiles.

How long does synthetic underlayment last under a roof?

When properly covered by shingles or metal panels, high-quality synthetic underlayment can last as long as the roof itself, typically 25 to 50 years. It provides a secondary layer of protection against leaks and moisture damage.

What is the difference between roof underlayment and waterproofing membrane?

Roof underlayment is a protective layer beneath roofing materials designed to resist moisture and provide backup waterproofing. Waterproof membranes are thicker and more flexible sheets used primarily under floors, walls, and roofs where complete water resistance is critical, such as showers and flat roofs.

Conclusion

Choosing the right roof underlayment or waterproof membrane is critical for ensuring long-term durability and protection for your home or project. High-quality products like the SIPA 100 GSM Synthetic Underlayment, ArmorLay 25, and Waterproof PE Membrane offer outstanding performance against moisture, UV rays, and temperature extremes.

Whether you are working on a steep metal roof, a residential tile installation, or a bathroom renovation, investing in premium underlayment materials safeguards your work against leaks, cracks, and costly repairs.

Explore the options reviewed in this guide and choose the best waterproofing solution to ensure your next project is built to last.