PVC Roofing Pros and Cons: Is It the Best Choice for Flat Roofs?

When it comes to flat and low-slope roofing, the battle is usually fought between three giants: EPDM (rubber), TPO, and PVC. While asphalt shingles dominate the residential pitched market, flat roofs require a completely different approach to waterproofing. Among the single-ply membrane options, Polyvinyl Chloride (PVC) is often regarded as the premium, high-performance choice.

But is the “Cadillac of single-ply” actually worth the extra investment? Whether you are a commercial building owner or a homeowner with a flat-roof extension, understanding the mechanics of this material is vital.

In this comprehensive guide, we will dissect the PVC roofing pros and cons, analyze its chemical structure, compare it against its rivals, and help you decide if this heat-welded fortress is right for your property.

What Exactly is PVC Roofing?

PVC roofing is a single-ply white membrane used on commercial and residential flat roofs. It is made from two layers of PVC with a polyester reinforcement scrim sandwiched in between. This “sandwich” structure is what gives the material its high tear strength and flexibility.

Unlike rubber roofing (EPDM) vs TPO, which are often glued or taped at the seams, PVC seams are hot-air welded. This process turns individual sheets of membrane into one continuous, monolithic barrier that is impervious to moisture.

The Secret Sauce: Hot Air Welding

The defining feature of PVC is the seam. Using a robotic welder or a handheld heat gun, the overlapping seams are heated to nearly 1,000 degrees Fahrenheit. The plastic melts and fuses together. Once cooled, the seam is actually stronger than the membrane itself. This eliminates the #1 cause of roof leaks: adhesive failure.

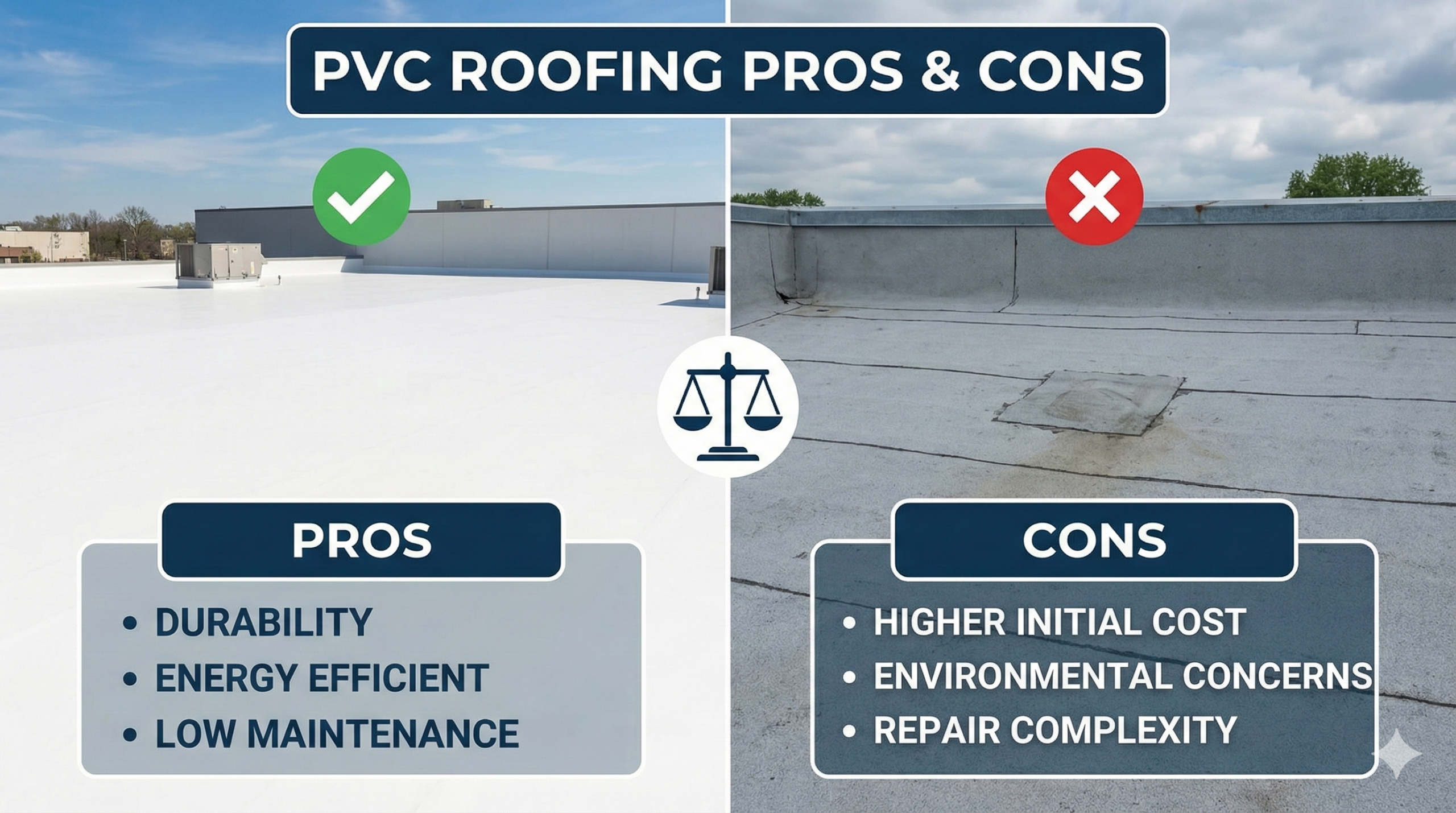

The Advantages: Why Choose PVC? (Pros)

PVC has been around since the 1960s, giving it a track record that newer materials like TPO are still trying to match. Here are the distinct advantages that keep contractors recommending it.

1. Unmatched Durability and Strength

PVC membranes are engineered to be tough. The polyester scrim reinforcement provides excellent resistance to tearing and puncturing. If you are worried about roof rats causing damage or birds pecking at the surface, PVC offers a much harder shell than rubber roofing. The American Society for Testing and Materials (ASTM) requires PVC to have a minimum breaking strength of 200 pounds per inch, which most manufacturers exceed.

2. Superior Chemical Resistance

This is the deal-breaker for many commercial applications. PVC is highly resistant to animal fats, greases, and harsh chemicals. If you are roofing a restaurant with roof exhaust fans venting grease, an asphalt or EPDM roof will dissolve and rot. PVC remains unaffected.

3. Fire Resistance

PVC is naturally fire-retardant. It is difficult to ignite and self-extinguishes when the flame source is removed. Most PVC systems achieve a Class A fire rating, which is the highest standard available. This is a critical safety feature for urban buildings.

4. Energy Efficiency and Cooling

White PVC roofs are highly reflective. They reflect UV rays rather than absorbing them, which can significantly lower cooling costs during the summer. If you are looking for how to keep your roof cool naturally, installing a reflective membrane is step one. This reduces the “heat island effect” in cities and prolongs the life of your HVAC equipment.

5. Resistance to Ponding Water

While no roof is designed to be a swimming pool, flat roofs often suffer from ponding water due to poor drainage or lack of roof crickets. Because the seams are welded rather than taped, PVC can withstand standing water better than many other systems without leaking.

Professional Heat Gun for PVC Repair

If you own a PVC roof, having a professional heat gun allows for permanent patches and repairs rather than relying on temporary sealants.

Check Price on AmazonThe Disadvantages: What to Watch Out For (Cons)

Despite its performance, PVC isn’t perfect. Here are the drawbacks you need to consider before signing the contract.

1. Higher Initial Cost

PVC is generally the most expensive of the single-ply membranes. The manufacturing process is more complex than TPO, and the installation requires specialized labor. When calculating the roof replacement cost, expect PVC to run 20-30% higher than EPDM or TPO.

2. Old Formulation Issues (Plasticizer Migration)

In the past, PVC roofs had a reputation for shattering in cold weather. This was due to “plasticizer migration,” where the chemical agents that made the roof flexible would evaporate over time. While modern formulations have largely fixed this, cheap, low-quality PVC can still become brittle after 15 years.

3. Difficult to Install

This is not a DIY-friendly material. Unlike installing shingles, PVC requires expensive welding robots and precise temperature control. If the welder is too hot, it burns the membrane; too cold, and the seam creates a “false weld” that will pop open later.

4. Material Incompatibility

PVC does not play well with asphalt. If you are installing PVC over an old tar roof, you must use a separator sheet. If the PVC comes into direct contact with asphalt fumes or oils, it will degrade rapidly.

Comparison: PVC vs. The Competition

To truly understand the pros and cons, we must look at how PVC stacks up against its main rivals: TPO (Thermoplastic Polyolefin) and EPDM (Ethylene Propylene Diene Monomer).

| Feature | PVC | TPO | EPDM (Rubber) |

|---|---|---|---|

| Seam Technology | Hot Air Welded (Strongest) | Hot Air Welded | Tape/Glue (Weakest point) |

| Chemical Resistance | Excellent (Best for restaurants) | Good | Poor (Degrades with oils) |

| Flexibility | Moderate (Can be stiff in cold) | Good | Excellent (Highly flexible) |

| Cost | $$$ (High) | $$ (Moderate) | $ (Low/Moderate) |

| Lifespan | 20–30 Years | 15–25 Years | 25–40 Years |

PVC vs. TPO

TPO is the “new kid on the block” and is cheaper than PVC. While TPO has gained massive market share due to price, PVC has a longer proven track record. TPO formulations are still being tweaked, whereas PVC is a known quantity.

PVC vs. EPDM

EPDM is a black rubber sheet (though white is available). It is easier to install and lasts a long time, but the seams are its Achilles heel. EPDM relies on adhesive tape, which eventually dries out. PVC’s welded seams make it superior for roofs with potential ponding water or those in hurricane zones where wind uplift is a major concern.

Installation and Maintenance Essentials

Even the best material will fail if installed poorly. Here is what you need to know about the process.

The Installation Process

PVC is typically mechanically attached or fully adhered.

- Substrate Prep: The deck must be clean. Insulation boards specifically designed for flat roofs are laid down.

- Underlayment: A separation layer or fire board is often required. Check the purpose of roof underlayment to understand why this layer matters.

- Roll Out: The membrane is rolled out and screwed into the deck using plates and fasteners.

- Welding: The overlap covers the screws, and the machine welder seals the seam.

- Flashing: All penetrations (pipes, vents) must be flashed using pre-molded PVC boots. Proper roof flashing is critical to preventing leaks.

Maintenance: Keep it Clean

While low maintenance, PVC is not “no maintenance.” You should inspect the roof twice a year.

- Check for punctures from dropped tools or debris.

- Clear drains to prevent weight stress.

- Inspect the “cold welds” (seams that didn’t fuse properly).

If you need to inspect a large commercial roof, consider using technology. The best drone for roof inspections can save you time and keep you safe on the ground.

Stay Safe on Slippery PVC

PVC membranes become incredibly slick when wet or dusty. Never walk the edge without proper fall protection.

Check Price on AmazonIs PVC Right for Your Climate?

Geography plays a role in your choice.

Hot Climates (Florida, Texas, Arizona)

PVC is king here. The reflectivity saves massive amounts of money on AC. Also, it stands up well to the humidity and doesn’t rust like metal can near the ocean. If you are wondering are metal roofs good in Florida, PVC is a viable alternative that offers similar wind resistance with better waterproofing on low slopes.

Cold Climates (Midwest, Northeast)

Modern PVC works well, but you must be careful about ice removal. Using sharp metal shovels can slice the membrane. You should learn how to remove ice dams safely using steam or calcium chloride rather than force.

Pros and Cons Summary Table

| The Pros (Why to Buy) | The Cons (Why to Skip) |

|---|---|

|

|

Frequently Asked Questions (FAQ)

Can I install PVC roofing myself?

It is highly discouraged. The equipment required (hot air welders) costs thousands of dollars, and the technique takes years to master. A bad weld means a leak. For DIY, EPDM is more forgiving, though professional installation is always recommended for warranties.

Does PVC roofing come in colors other than white?

Yes, while white is the most common for energy efficiency, manufacturers produce tan, gray, and even custom colors to mimic metal or synthetic slate roofing aesthetics. However, darker colors lose the energy-saving benefits.

How do I find a leak in a PVC roof?

Leaks usually occur at penetrations (vents, pipes) or seams. On a white roof, dirt often accumulates near the low spot where the water enters. You can check our guide on how to find a roof leak for general tracing tips, but on PVC, you are looking for cuts or separated welds.

Can I put solar panels on a PVC roof?

Absolutely. PVC is an excellent substrate for solar because it is durable and the reflective surface can actually boost the efficiency of bifacial solar panels. If you are considering if solar shingles are worth it, remember that on a flat roof, rack-mounted panels on PVC are the standard.

Conclusion: Is PVC the Winner?

PVC roofing is a powerhouse in the flat roofing industry. It offers a blend of durability, energy efficiency, and chemical resistance that is hard to beat.

Choose PVC if:

- You are roofing a restaurant or industrial facility with chemical vents.

- You live in a hot climate and want to maximize energy savings.

- You want the peace of mind that comes with heat-welded seams.

- You plan to own the building for 20+ years.

Consider Alternatives (like TPO or EPDM) if:

- Budget is your primary constraint.

- You are doing a simple garage roof with no chemical exposure.

- You prefer a black roof for heating benefits in a very cold climate.

Ultimately, a roof is only as good as the installer. Ensure you hire a certified contractor who specializes in heat-welded systems to get the full benefits of this premium material.

Ready to Start Your Project?

Make sure you have the right gear, from tape measures to safety harnesses.

Browse Roofing Supplies on Amazon